1930's Watling-Bell Nickel Slot Machine

Sometime in the 1940’s my grandfather bought a used nickel slot machine for $25, much to the consternation of my grandmother. Generations of children and family guests ran countless nickels through the thing, until my grandparents moved to a retirement home in the late 70’s. After that it moved to my room, making it’s delightful mechanical racket for another several years until one of the wheel stop levers broke from metal fatigue.

By that time I was in late high school, with other things weighing on my mind, so the slot machine was left idle. The poor thing moved from one place to another for the next 20 years. Finally in the early days of the 21st century I prevailed upon my dad to fix the broken part. When I got the piece back I happily installed it, put a nickel in the slot and pulled down the handle.

What a disappointment. The 70 year old grease and oil had turned to something more like wax, and it couldn’t get through a cycle without wheezing to a halt. A bit of oil and a few more cycles and it would at least run, but when I showed it to my wife she was less than excited about the sad condition of the machine. The verdict was “Not suitable for display in the house”.

Clearly a serious restoration was in order, but we had plenty of other stuff going on in our lives at the time. A year or so later, in the spring of 2004 I sat down to work on it in earnest. I took more pictures, dismantled the case and started in on the mechanism itself.

Over the next month or so I cleaned two sub-assemblies, the reel stop and the coin chute. The rest of the guts were a worse mess, filthy with old grease and oily dust. I couldn’t face more hours of incredibly tedious work with orange solvent, paper towels, a toothbrush and a wire brush. I gave up, and the partially eviscerated mechanism sat on my workbench for five years, mocking me.

Later a friend told me I needed a project to take my mind off my career doldrums, “and not a programming project!” He told me about building furniture in his garage, and I realized that the slot machine was the perfect project for me.

This time, instead of laboriously degreasing each part by hand, I decided to seek professional help. Once I disassembled the mechanism, I took the parts to a local machine shop, and they ran them through their “dishwasher”, which uses soap and high pressure hot water to remove all traces of gack, grunge and grime. I still have to wire-brush the parts and rub them with a lightly oiled cloth, but it’s so much easier than mucking about with solvent and a toothbrush.

(Eventually I’ll get ‘round to posting the results…)

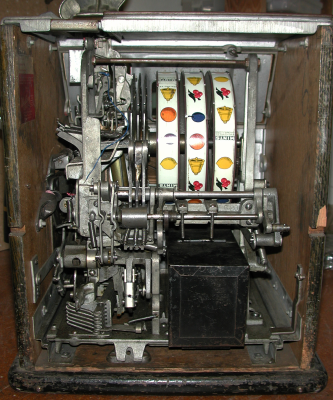

Open the back, and you can

see the fun

parts.

Open the back, and you can

see the fun

parts.

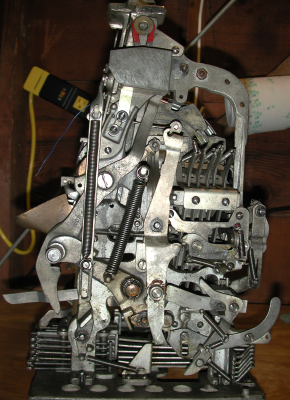

The mechanism slides out of the

case, revealing its rather daunting

complexity.

The mechanism slides out of the

case, revealing its rather daunting

complexity.

Left inside the case is the jackpot

assembly.

Left inside the case is the jackpot

assembly.

I took apart the case completely,

so I can clean, polish and (maybe) repaint

it.

I took apart the case completely,

so I can clean, polish and (maybe) repaint

it.

Not much left when you pull off all

the metal

parts.

Not much left when you pull off all

the metal

parts.

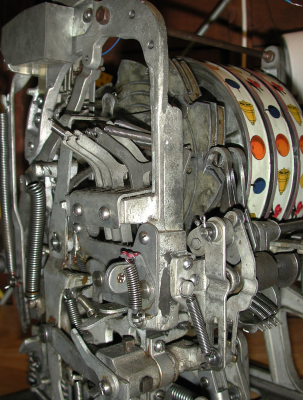

These parts are clean and ready

for

reassembly.

These parts are clean and ready

for

reassembly.

The frame, wire-brushed, lightly

oiled, and

reassembled.

The frame, wire-brushed, lightly

oiled, and

reassembled.

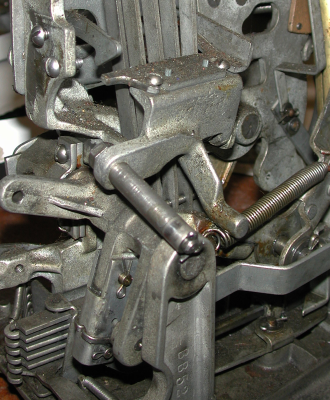

The “UI” of the

machine.

The “UI” of the

machine. Rube Goldberg would be

proud.

Rube Goldberg would be

proud. It was amazingly

filthy.

It was amazingly

filthy. This is what the parts looked

like when they came back from the machine shop. Bone dry, with a light

coating of soap

scum.

This is what the parts looked

like when they came back from the machine shop. Bone dry, with a light

coating of soap

scum.